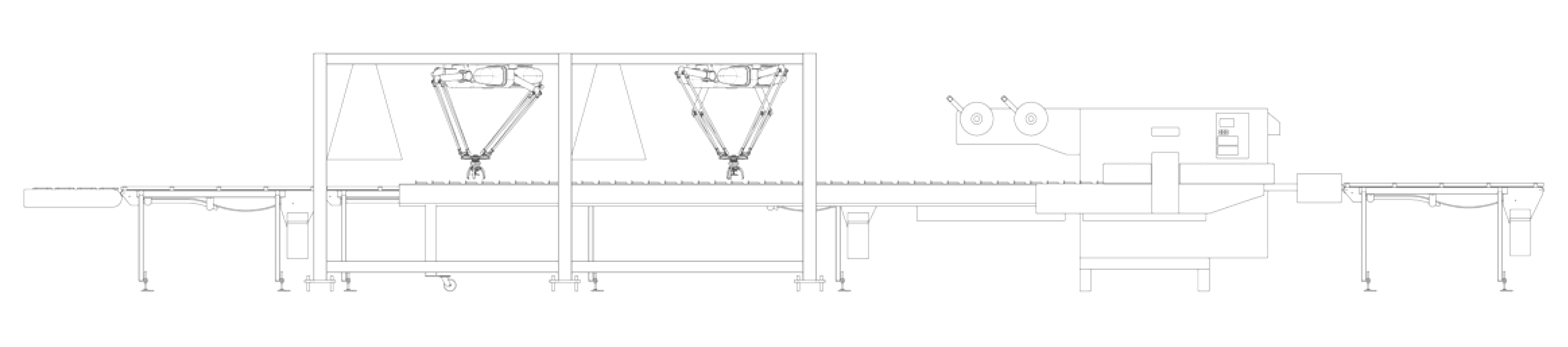

ROBOTISED PICK & PLACE LOADING

ROBOTISED PICK & PLACE LOADING

CUSTOMISED

Our loading processes are adapted to your packaging machines – flow wrappers, thermoformers, sealing machines etc.

HIGH OUTPUT

Integration of delta robots which enable a single-handling

output of 120 products/minutes.

ADAPTABLE

Loose products, production areas, difficult-to-handle products.

HYGIENIC

FDA/USDA-certified materials, micro-bead blasted finish,

inverted tube.

Output

Up to 120 products single-loaded.

Debulking

- Product alignement.

- Separating sticky products (patented system).

Quality check vision system

- Integration of a 2D or a 3D vision system.

- Shape, colour, discrepancy controls.

Automated loading

- Choice of robot according to the product, single product loading or multiple product loading.

- Product preserved during loading.

Meat (steak, fillet, diced etc.)

Bread

Snacks (spring rolls, shells etc.)