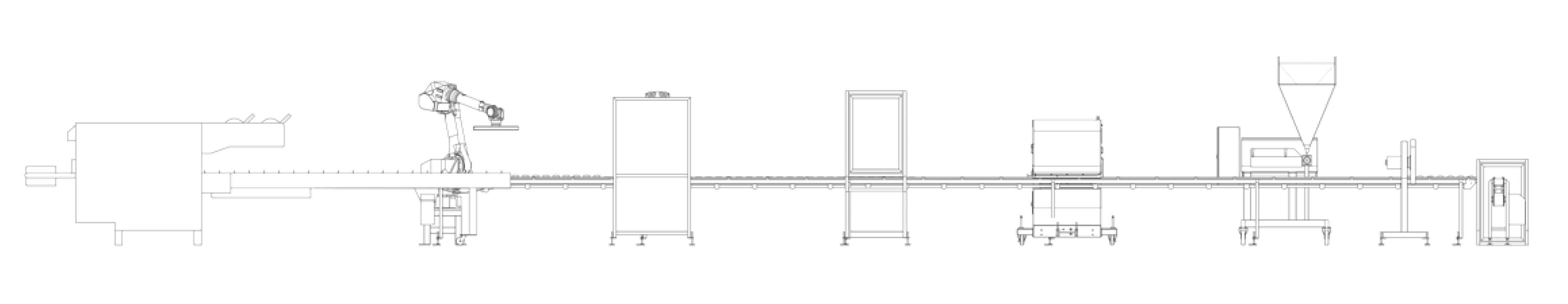

AUTOMATIC HAMBURGER

AUTOMATIC HAMBURGER

ASSEMBLY LINE

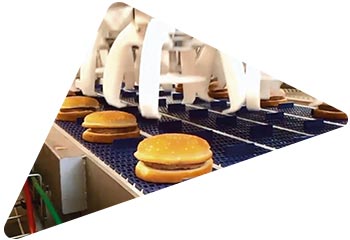

Bacon slicing

and automatic placement

Automatic placement

of frozen burgers

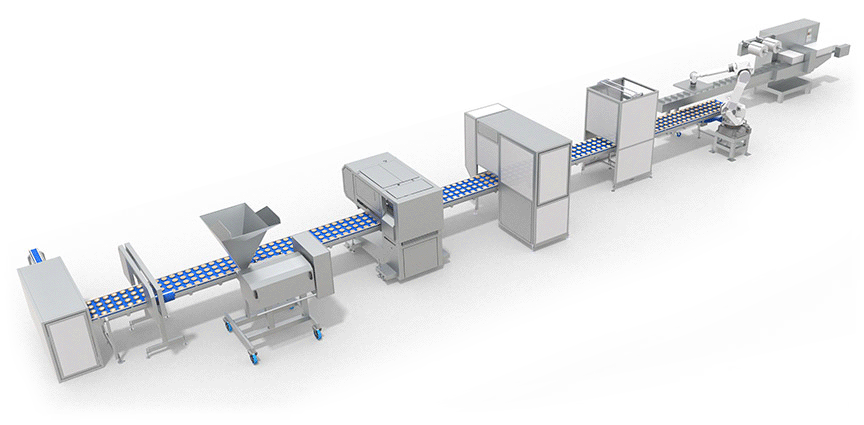

Automated packaging

machine loading system

HYGIENIC

FDA/USDA-certified materials, micro blasted finish,

inverted tube.

HIGH PERFORMANCE

Precise assembly of the products, high output line, high

efficiency.

AUTOMATED

All operations are automatic: positioning (buns, beef, cheese), cutting, dosing, assembling, by using simple procedures.

CUSTOMISED

Line designed according to your final product, process adapted to the existing environment, integration of your machines.

Output

Processes running up to 150 products per minute, per line.

processes running up to 150 products per minute, per line

Using MCA technology.

Positioning of beef patties

By shuttle conveyor.

Positioning of cheese

Slicing directly on the line or dosing.

Automated loading of the finished product.

In flowpack wrappers, boxes or in thermoformers.

Freezing

By spiral or tunnel freezer.

hamburger in many configurations

Fresh or frozen buns, square, round, bagels etc.

Sliced or liquid cheese.

Ketchup, mayonnaise, with or without particulates.

Burger: beef, chicken, fish, potato patties, veggie

burgers etc.