READY MEAL

READY MEAL

PROCESS

More information :

Our partners

HIGH PERFORMANCE

Compliance of the product, high output, optimised efficiency

HYGIENIC

FDA/USDA-certified materials, micro-bead blasted, inverted

tube.

CUSTOMISED

Line built according to your final product: fresh, frozen,

pasteurised. Process adapted to the existing environment, integration of your machines.

FLEXIBLE

Numerous recipes, user-friendly access using a touch screen,

automated recipe change, cleaning time reduced between series.

Output

- 40 products per minute per lane.

- Lines from 1 to 6 lanes.

Denesting

- Multi-format.

- Quick change over.

- High autonomy.

Volume dosing system

- High precision.

- Servomotor technology.

- Adapted to difficult products.

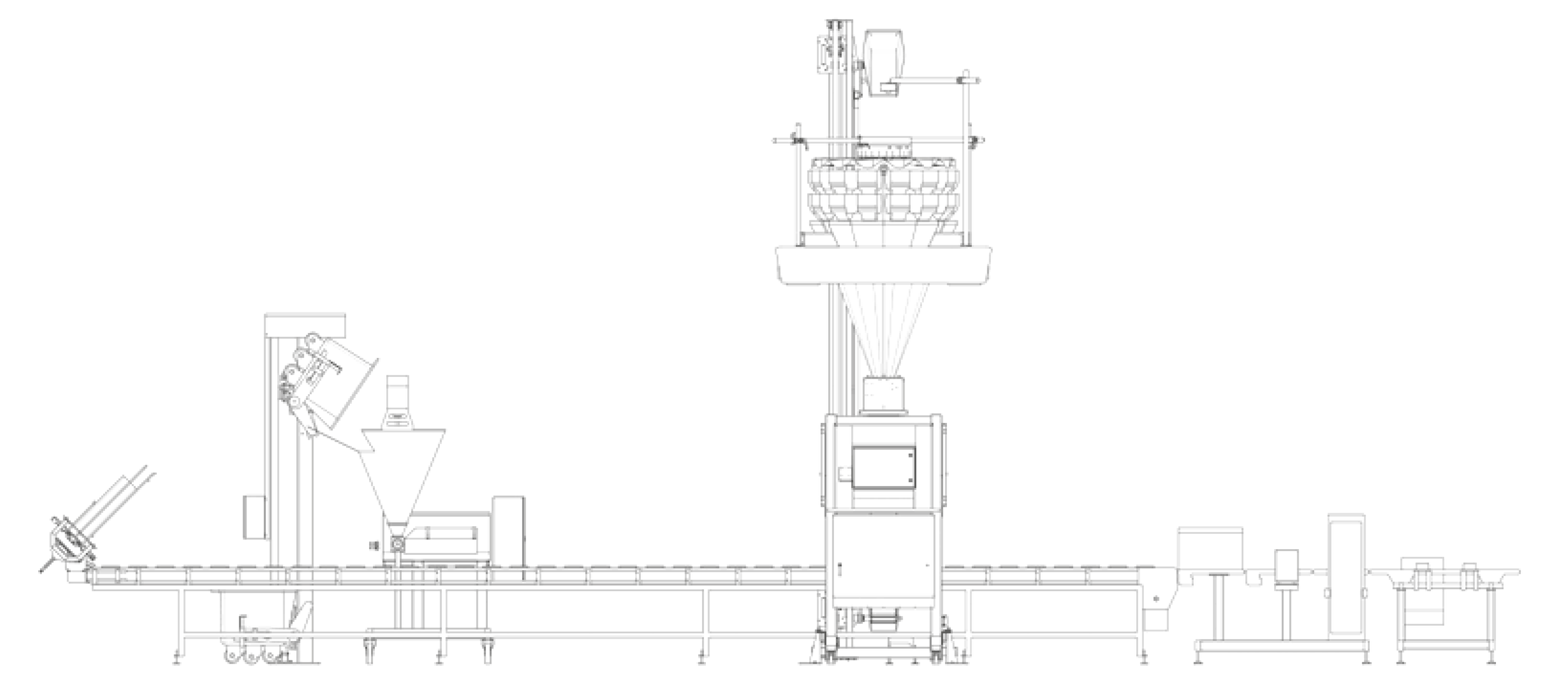

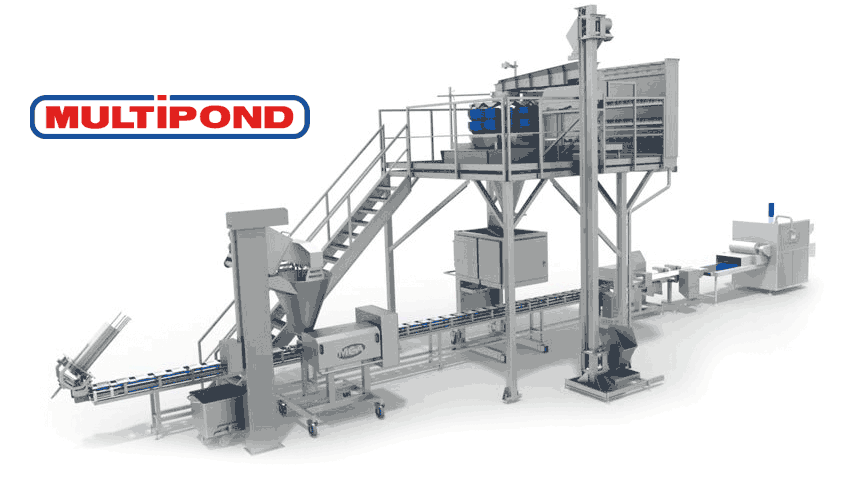

Multihead weighing

- Multipond weighing device integration.

Integrated environment

- Topping.

- Clipping.

- Dynamic weighing.

- Packaging etc.

Meat, rice, pasta, purées, sauces (with/without particulates), mixed salads, grated cheese, herbs etc.

Round/rectangular trays, bowls etc.

Thermoformed/injected trays, boxes, aluminium

etc.