An efficient R&D department, a design office for 20 people

Each project is a unique challenge, which mobilises all of the MCA Process teams. The research department (20 people) is integrated into the company. Commercial technicians, designers, computer scientists, engineers, mechanics and automaticians work together, with a great demand and a true sense of service. Cooperation with the customer is therefore essential and commonplace.

Innovative, state-of-the-art solutions

A team of experienced sales engineers creates and develops processes meticulously adapted to each product. Passionate, rigorous and attentive, at the forefront of the latest technologies, R&D staff are always looking for the best.

They imagine innovative solutions, all different from each other. The mechanical-automation R&D office (about twenty people) defines and examines in detail all the needs, according to the special features of each environment. The more complex the better!

Real-world testing

Beyond the R&D laboratory, a test laboratory allows real-world testing, even for difficult products. Thanks to numerous tests, MCA Process leads to the validation of efficient, robust and perennial tools.

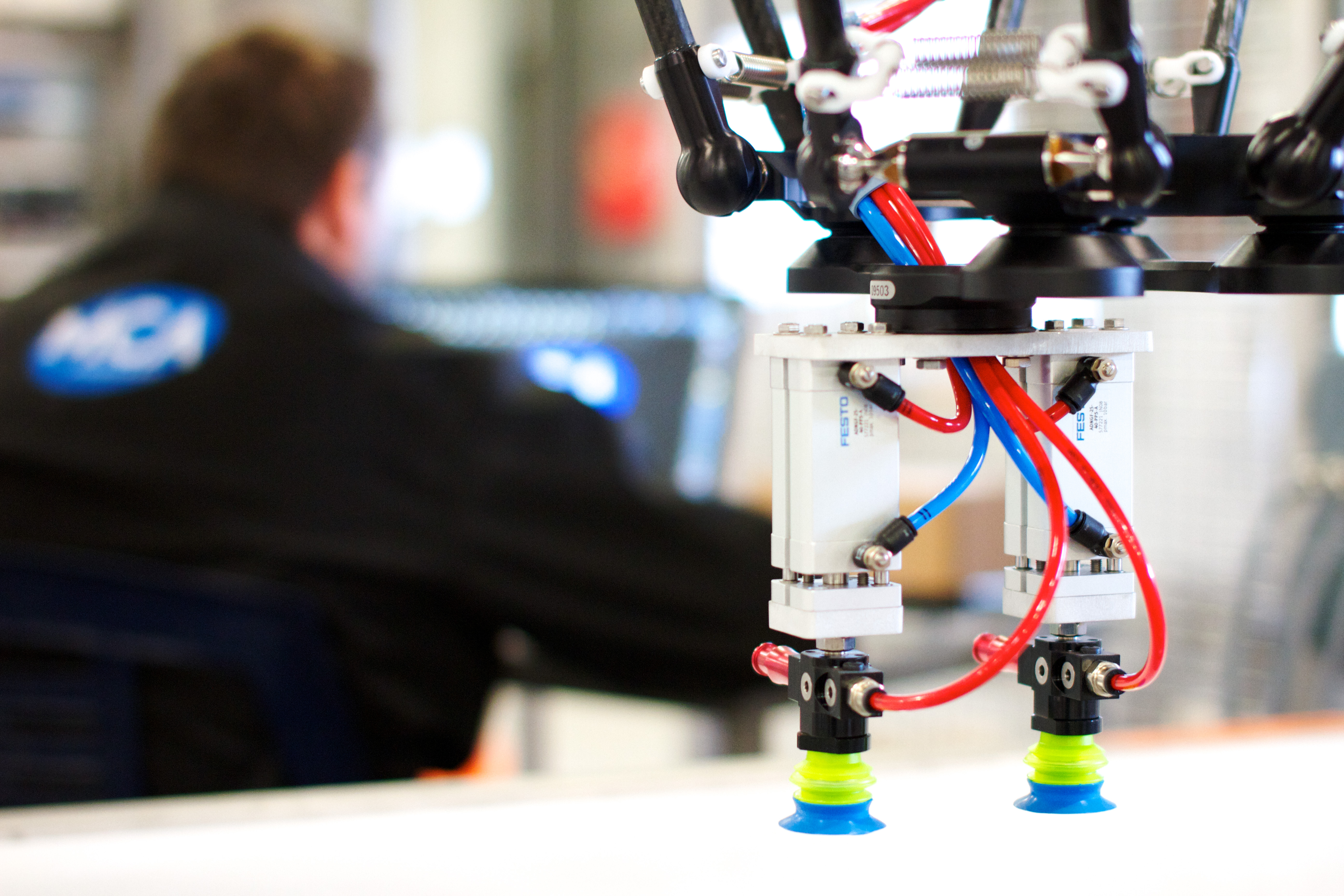

This engineering capability is also reflected in various patents, for example for robot heads, without any other equivalent. Another major competence of MCA Process is the handling of products, with the possibility of taking heavy products (for example, 20 kg hams), delicate products (crêpes) or specially shaped ones (scallops), turning them over, transport them and position them very precisely.

Recognized experience and methodology

All requests are very different, MCA Process adapts. Among its recognized areas of expertise are: meat applications, product handling and pick-up, including bare products (up to one tonne). We have lots of references in chopped steak, hamburger, and prepared dishes.

Production monitoring is precise, with on-site training of operators. MCA Process guarantees the optimal use of each process. A camera can troubleshoot live or a technician can go to the location.